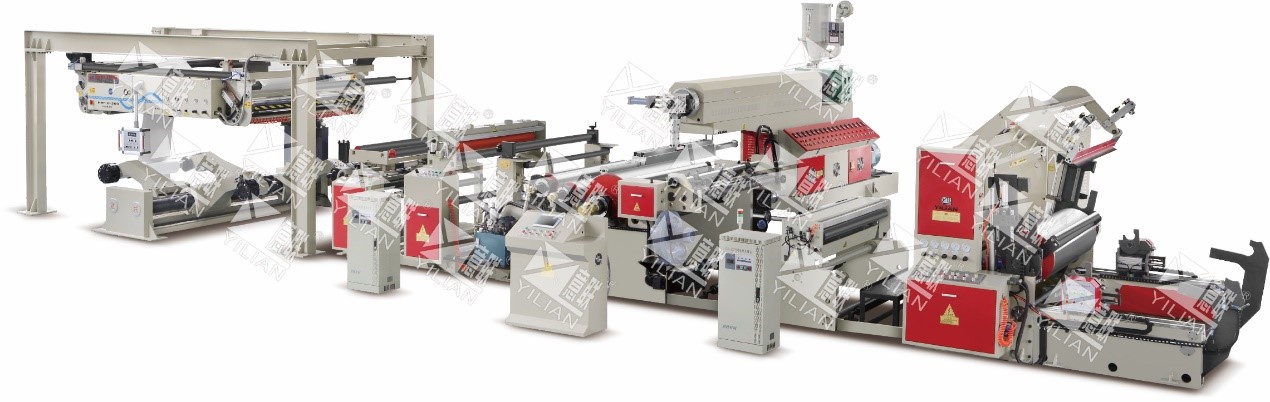

WSFM1300C Automatic Paper PE Extrusion Coating Machine

| Suit laminating resinae | LDPE、PP etc |

| Causa basis materialis | paper(80-400g/m²) |

| Max mechanica velocitate | 300m/min (propediem operatur in crassitudine litura dependet, latitudo) |

| Latitudo coating | 600-1200,dux cylindro width:1300mm |

| Crassitudo coating | 0.008-0.05mm (Single cochlea) |

| Crassitudo coating error | ≤±5% |

| Auto tensio occasus range | 3-100kg plena margine |

| Max extruder quantitas | 250 kg/h |

| Compone refrigerationem cylindro | 800×1300 |

| Screw Diameter | ∅110mm ratio35:1 |

| Max solvuntur diametri | 1600mm |

| Max rewind diameter | 1600mm |

| Unwind paper core dia: 3″6″ et Rewind paper core diameter:3″6″ | |

| Extruder agit 45kw | |

| Summa potentia | circiter CC Kw * |

| Apparatus pondus | de 39000kg |

| Extra dimensionem | 16110 mm×10500 mm 3800 mm |

| Apparatus corporis color | Cinereo et rubro |

1. Unwind part with PLC, servo dissolvens.

1.1 Reteeta compage

Structura: HYDRAULICUS frame-minus rudentis

Series BA splicer partem laminationis lineae integralem format et super volumen constituitur sub structura pontis stant. Continuitatem permittit in currendo chartae praesentis ad volumen chartae proximae sine sistenda productione.

Infra tabulae laterales splicer sunt 2 caput mobile evulsio et sectio centralis mobilis sustentationis. Superius sunt 2 nip rotulae.

Volumen capstan, e converso otiosior volvunt et duplex systema saltatoris chartam cumulationis sectionis formant, quae chartam usque ad 4 tempora longitudinis sculptoris accumulare potest.

Machina per panel operationem in machina operatur

Charta ligans celeritatem Max.300m/min

a)cum charta vi supra 0.45KG/mm,max. 300m/min;

b)cum charta vi supra 0.4KG/mm,max. 250m/min;;

c)cum charta vi supra 0.35KG/mm,max. 150m/min;;;

charta latitudine

Maximilianus. 1200mm

Min. 500mm

CE-300

Maximilianus. 300m/min

Pneumatica notitia

Set pressura 6.5 talea

Min. pressura VI talea

Exemplar CE-300

Potentia 3.2kVA, 380VAC/50Hz/20A

Imperium voltage 12VDC/24VDC

1.1.1 Independens hydraulica scapi fusi fibulae brachii genus duplex opus stationis explicans-sine stipite aereo-hydraulico loading, nisi sumptus onerationis structurae mechanicae. Automatic AB scapus auto- reel alternatio, materia minus vasta.

1.1.2 Maximilianus. rudentis dia.:¢1600mm

1.1.3 Auto tensio occasu range 3-70kg plena margine

1.1.4 tensio praecisio:± 0.2kg

1.1.5 paper core:3"6"

1.1.6 Tension control system: harundo genus tensionis detectoris per praecisionem potentiometer tensionis deprehensio, centralised imperium programmabilis PLC

1.1.7 Coegi imperium systemPIH cylindrici braking, in gyratorius encoder cito feedback, praecisio pressionis regulandi valvae clausa ansa imperium, programmabilis moderator PLC centralised imperium

1.1.8 Tension setting: By the precise pressure regular valvae setting

1.2 Repono genus automatic legendo, cutting fabrica

1.2.1 Repono quiddam motore pneumatico agitatum, tensio stabilis efficiat cum chartam legendo.

1.2.2 separatum compages

1.2.3 PLC auto- hastile gyratorium novum computare, et celeritatem principalem continere

1.2.4 Accipe materiam torcular cylindro, dromonem materialem .tensionis imperium mutatione fractum, reset omnes automatice consummare possunt

1.2.5 Rollerus prae terrorem mutabit,: diametri opus cum ad 150mm perveniet, machina terrebit

1.3 Rectifying control: photoelectric putter rectificare imperium systema (bst structure)

2. Corona (Yilian nativus)

Coronae curatio potentiae:20 kw

3. HYDRAULICUS lamination unit.

3.1 Tres umbilici laminae compositi compages, dorsum prelo cylindrus, mixtus cylindrus etiam vires ferre potest, composita solida.

3.2 Exspoliatio cylindri pii Flexilis: productum compositum facile pervidere ab cylindro refrigerante, hydraulicum arcte premere potest.

3.3 Curvum volumen cinematographicum adulationis structurae,: velum celeri instruere potest

3.4 Compositum feed materialis cylindrus adjust crassitudine materiam pelliculare potest superare inaequale et sic in infirmitatem

3.5 Celsus pressus flatu exiguo sugit ore cito.

3.6 Compone exitum dromonem cylindro

3.7 Compositum cylindro a motore dependens agitatur

3.8 Compone cylindro agitato motore ab Iaponia frequentiae moderatoris regitur

Spec:

1) compositis cylindro 800 1300mm 1pcs

2) rubber cylindrus 260 × 1300mm 1pcs

3) press cylindro:¢ 300 1300 mm 1pcs

4) componens oleum cylindricum: ¢63 150 2pcs

5) DECRUSTO cylindro:¢130 MCCC 1pcs

6)11KWmotor(SHANGHAI) 1set

(7)11KW Frequency converter (JAPAN YASKAWA)

8)rotate connector:(2.5"2 1.25"4)

4. Extruder (auto altitudo adjusting)

4.1 diam stupra: ¢ 110, Max extruder de: 250kg/h Iaponica technologia.

4.2 T-die( Taiwan GMA)

4.2.1 Mold width:1400mm

4.2.2 Mola latitudo efficax: 500-1200mm

4.2.3 Mola labii gap:0.8mm, crassitudine efficiens: 0.008—0.05mm

4.2.4 Crassitudo coating error≤±5%

4.2.5 Tubus electricus calefactio intus calefactio, alta calefactio efficacia, temperatura celeriter crescens

4.2.6 Prorsus inclusum locum, Repensationem width commensurationem

4.3 Celeri mutatio network cogitationes

4.4 Ante et retro ambulans, sponte Trolley levare potest, range :0-100mm

4.5 Mola 7 areas temperatus imperium. Screw dolium 8 sectione temperatura temperantiae. iungo 2 aream temperaturae moderamen infrared calefactionem adhibet.

4.6 Magna potestas reductionis calces arca, DENS DENS (Guo tai guo mao)

4.7 Digital temperature controller automatic temperatus control

Partes principales:

(1) 45kw AC motor (SHANGHAI)

(2) 45KW frequency converter (JAPAN YASKAWA)

(3) Digital temperatura moderatoris 18pcs

(IV) 1.5KW ambulans motor

5.Pneumatica circum cultrum torulo fabrica

5.1 Cochlea Trapezoidalis transversalis fabrica aptans, latitudinem chartae secans muta

5.2 Pneumatica Pressura dromonem

5.3 5.5kw princeps pressura ore absorbet

6.Rewinding Unit 3D gravis officium compages

6.1 Rewinding Artus

6.1.1 Frictio genus electricum duplices stationes machinae rewinding, alta velocitate latae sectionis et materiae confectae legendo, automatic exinanitio est.

6.1.2 Maximilianus. rewinding diameter:¢ 1600 mm

6.1.3 volvunt-in velocitate:1r/min

6.1.4 contentio:3-70kg

6.1.5 Tension precision:± 0.2kg

6.1.6 paper core: 3″ 6″

6.1.7 Tensio Control System: Pulvinus cylindrus fluitantis cylindri structurae genus innatat, tensio potentiometri praecisione deprehenditur, et programmabilis moderator PLC tensionem centraliter moderatur. (Japan SMC cylindri friction humilis) 1 set

6.1.8 Coegi Control System: coegi motoris 11KW, encoder celeritatis feedback in gyratorium, Senlan AC inverter dual clausus-loop imperium, programmabilis moderatoris PLC centralised imperium. 1 set

6.1.9 Constans Tensio Profectus: Subtilitas Pressura Regulator Occasus (Japan SMC)

6.1.10 Taper tensio occasus: arbitratu a screen computatrum, PLC potestate, conversio ratio electrici/aeris (Iaponia SMC)

6.2 Lorem Pascendi et Secans Fabrica

6.2.1 Splicing Support Rollers reguntur a PLC motore ut teneant materiam ab attritu cylindro

6.2.2 HYDRAULICUS Lorem Cutter Mechanismum

6.2.3 PLC computatio latae sententiae legendi processus, conlocatio voluminis cum clavis perficitur

6.2.4 Function of Supporting Roller, cutting material, Reset, etc

6.2.5 Formularium

(1) Friction cylindrus: ¢700x1300mm 1 bar

(2) Curvis motor: 11KW (Shanghai Lichao) 1 set

(3) Devolvere calces arca: calces helical superficiem indurata reducer (Thailand Mau)

(4) Inverter: 11KW (Japan Yaskawa) 1 set

(V) calces cylindro Support arca: I paro of vi

(VI) Volo reducer: dens durum I paro of vi

(VII) Rolling ambulans celeritatem reducer: 1 paro of vis

(VIII) fungens hydrau

7.Auto vector aer

8.Drive Section

8.1 Praecipuum motor, transmissio cingulum synchronum capit cingulum

8.2 Compounding, rewinding and unwinding motor: Coegi balteum adoptare arcus calces, catena et cingulum synchronum transmissio

8.3 Praecipua archa calces coegi: signantes oleum immersum calces helicas, linea calces helicae tradendae structurae

9.Control Unit

Scrinium electricae independens, imperium centralisatum, locus compositus cum operatione arcae ditionis centralised. Machina automationis systematis PLC hollsys instrumenti utendi cum facultate processui alta, et homo apparatus dialogus significat communicationem retis inter interfaciem utentem. PLC, extrusio unitatis, dialogus apparatus hominis interfaciendi rationi pulsis et systematis activitatis integrae constituunt. Pro quolibet ambitu latis calculi, memoriae, detectionis, terroris, etc. Poni possunt tensiones visivae fabricae, velocitatis, crassitudinis, tunicae, celeritatis et conditionis diversae operationis.

10. alii

11.1 Rector Roller:Hard anodization of aluminium offensionis volumen ductor, processus motus

11.2 Maximum voltage apparatus Gallia Schneider, omron Iaponia, etc.

11.parts notam

11.1 PLC(Beijing Hollysys)

11.2 Tactus screen(TAIWAN)

11.3 frequency converter:Japan Yaskawa

11,4 principalis motricium: SHANGHAI

11.5 humilis friction cylindricus(Iaponia SMC)

11.6 AC CONTACTOR(Schneider.

11.7 button(Schneider)

11. Static mixer(Taiwan)

11.9 cylindrici pressura regulans valvae (Taiwan)

11.10 Magnetica valvae commutatio (Taiwan)

11.11 pressio accuratio valvae regulantis.

12.Customer se praebet facilities

12.1 ipsum spatium et fundamentum

12.2 Facility supply for Machine electrical cabinet

12.3 Aquae copiae ad apparatus facultatem in porta et extra (emptor aquam frigidam praeparat)

12.4 Gas copiam machinae inclusae et e stomatalibus

12.5 Exhaurire fistula et ventilabrum

12.6 Collecta, onerans et exonerans materiam basin instrumenti perfecti

12.7 Aliae facultates non enumerantur in contractu

13. Parce partes indicem;

| Nec. | Nomen | Spec. |

| 1 | Thermocouple | 3M/4M/5M |

| 2 | Temperature moderatoris | Omron |

| 3 | Valvae Micro-regulandi | 4V210-08 |

| 4 | Valvae Micro-regulandi | 4V310-10 |

| 5 | propinquitas switch | 1750 |

| 6 | Nullam solidum | 150A和75A |

| 7 | itinerantur switch | 8108 |

| 10 | calefactio unitatis | ϕ90*150mm,700W |

| 11 | calefactio unitatis | ϕ350*100mm,1.7KW |

| 12 | calefactio unitatis | 242*218mm,1.7KW |

| 13 | calefactio unitatis | 218*218mm,1KW |

| 14 | calefactio unitatis | 218* 120mm, 800W |

| 15 | Schneider button | ZB2BWM51C/41C/31C |

| 16 | caeli galli | |

| 17 | Princeps temperatus tape | 50mm* 33m |

| 18 | telflon tape | |

| 19 | Corona cylindro cover | 200*1300mm |

| 20 | Aeris sheet | |

| 21 | screen filter | |

| 22 | Circulare fuperius | 150*80*2.5 |

| 23 | iungo pneumatica | |

| 24 | aer gun | |

| 25 | aqua iuncturam | 80A和40A |

| 27 | ANISOCYCLUM et alii | |

| 28 | drag catena | |

| 29 | instrumentum archa |

Partes praecipuae et picturae;

Exstructor (Auto splicer) → Tela dirigens → Corona tractator → Extrusio et pars componentis Edge qr → Rewinding